Anti explosion proof lamps in the food factory lighting in the fundamental role and application guidelines

First, why food factories have to choose Anti explosion proof lamps? Safety and compliance double guarantee

Food factory environment often exists in flammable gases, dust or humid areas [such as cold storage, cleaning workshop], ordinary lighting equipment is prone to trigger an explosion or short-circuit risk.

Anti explosion proof lamps approved special structural design [such as explosion-proof housing, corrosion-resistant materials], IP65/66 protection level, effectively isolate sparks and combustibles contact, to ensure a safe production environment, while meeting OSHA, ATEX and other international safety standards.

Second. Amasly Anti explosion proof lamps four core advantages: to enhance the lighting efficiency and safety of food factories

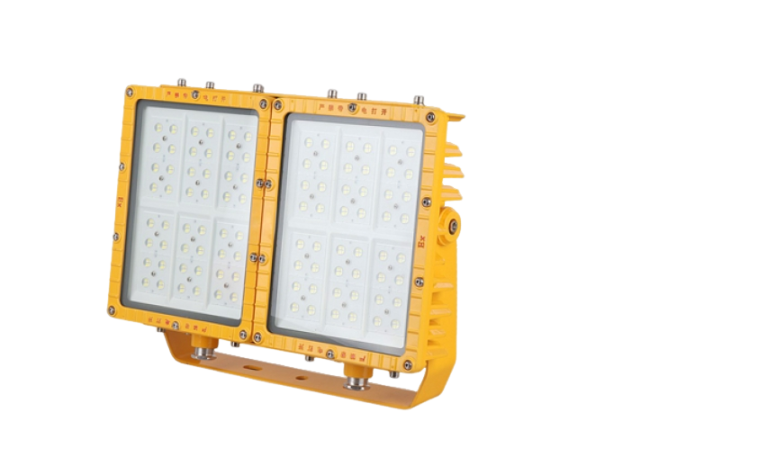

1. Excellent explosion-proof performance: sealed structure, preventing the internal arc or high temperature triggering an explosion in the external environment. 2. corrosion resistance and easy to clean: the light can be used in a wide range of environments.

2. corrosion-resistant and easy to clean: stainless steel or die-cast aluminum surface treatment to resist corrosion of common chemical cleaning agents in food factories.

3. energy-saving and long-lasting: LED Anti explosion proof lights luminous efficacy of 150LM / W, life expectancy of more than 50,000 hours, reducing the frequency of maintenance and energy costs.

4. Flexible adaptive scene: support hanging, wall mounted and other installation methods, covering production lines, warehouses, filling areas and other different areas.

Third, the food factory explosion-proof light selection guide: match the basic parameters of demand

1. Risk level of the area: according to Zone 1/Zone 2 to choose the corresponding explosion-proof level [such as Ex d IIB T4].

2. Lighting requirements: 500-1000 Lux illumination is required in the high-precision work area, and can be reduced to 200-300 Lux in the storage area.

3. Material and protection: 316 stainless steel is preferred for humid areas, and additional dust cover is required for dusty environments.

4. Certification guidelines: ensure product approval ATEX, UL or GB3836 certification to avoid compliance risks.

Fourth, the case analysis: explosion-proof lights how to deal with typical lighting pain points in food factories

A large dairy processing plant has been due to the lack of sealing of traditional lamps and lanterns lead to equipment short-circuit, after the replacement of AMASLY Anti explosion proof lamps:

Accident rate reduced by 60%, the annual maintenance cost savings of 40%; workshop illumination uniformity increased by 35%, quality control efficiency increased by 20%; energy consumption reduced by 30%, the annual carbon emissions decreased by 15 tons.

Fifth, Anti explosion proof lamps installation and maintenance: practical tips to extend the life of the application

Installation points: to avoid direct light on the raw material area, the use of decentralized layout to reduce the shadow;

Regular inspection: quarterly cleaning of heat sinks and lenses, testing the aging of seals;

Fault prediction: If the lamps and lanterns frequently flicker or temperature rise abnormally, need to immediately disconnect the power troubleshooting.

FAQ: Common questions about Anti explosion proof lamps in food factories

Q1:Food factory has no flammable gas, why still need explosion-proof lights?

A: In addition to gas, flour, powdered sugar and other suspended dust to reach a certain concentration will also cause an explosion, Anti explosion proof lights can fully prevent such risks.

Q2: How to determine whether Anti explosion proof lamps comply with the hygiene guidelines of the food industry?

A: Choose products with FDA or EHEDG certification to ensure that the material is non-toxic and the surface is smooth and easy to clean.

Q3: What is the maintenance cycle for explosion-proof lights?

A: It is advocated that the cornerstone inspection should be carried out every 6 months, and shortened to 3 months for humid or high-frequency cleaning areas.

Q4: LED explosion-proof lights are more energy efficient than traditional light sources?

A: Yes, LED Anti explosion proof lamps energy consumption by 50% -70%, and no mercury pollution, in line with the intention of sustainable development of food factories.

Q5:Can Anti explosion proof lamps be used in low-temperature cold storage environment?

A: You need to choose to hold help -40 ℃ operation models, and with anti-condensation design, to avoid low-temperature icing affect performance.